In 2018, an existing line, that consisted of a robotic complex of welding components and a line of laser welding of steel pipes for fireplaces, with a wall thickness of 2 mm was added.

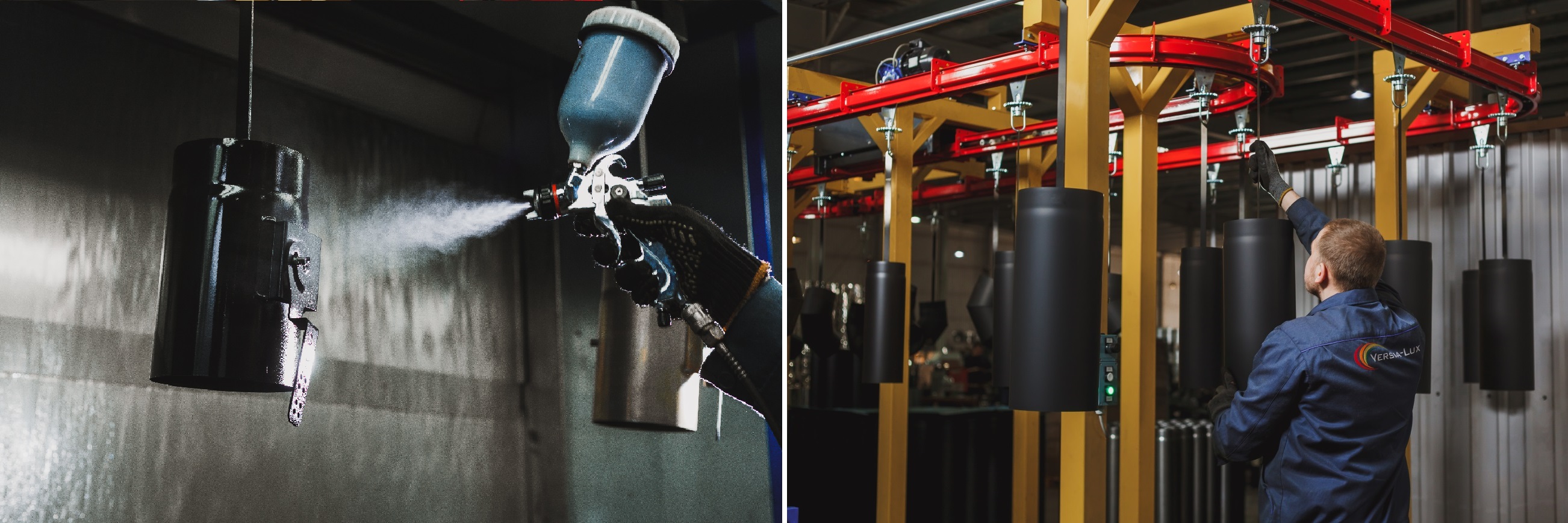

This line was complemented by the automatic full cycle coloring line, which includes cleaning, painting and baking of finished products at a temperature of 250 ° C.

|

|

Automatic full cycle coloring line

Elements for fireplaces, with a wall thickness of 2 mm, are produced on modern European equipment.

Quality and durability of the elements is ensured by the following factors:

- Laser welding of elements;

- Cutting of elements on 3D cutting laser;

- Welding of shaped elements on robotic complexes;

- Degreasing, dyeing, drying on an automatic full cycle coloring line.

The use of laser and robotic systems provides:

- Reliable and sealed weld, able to withstand high temperatures;

- High accuracy of elements geometry.

The use of a full cycle coloring camera ensures:

- Guaranteed cleaning of the element before painting and coating the metal with a nanoceramic film, that gives high corrosion resistance and a qualitative surface for painting;

- Application of high-temperature paint of European production, that guarantees the quality and durability of the coating;

Presence of a sintering cycle of a paint for full hardening takes place at a temperature of 250 ° С for 30 minutes. This allows you to apply items immediately, without pre-firing.