Important to know

There is no need to say that technological progress does not stand still, and technologies are improving from year to year. Today, you can heat a house with boilers that have an efficiency greater more than 100%, or use the alternative kinds of fuel, burning it in the solid fuel boilers! Selection of heating devices is very diverse, but they all require one thing - reliable chimney system.

Examples of brick and galvanized chimneys

Chimneys on the photo makes it clear that neither the clay brick, nor zinc, and especially steel is suitable for the manufacture of chimney systems for modern heating appliances. The above

materials are destroyed by condensate exposure for 1-2 heating season.

Unfortunately we still have to deal with poor quality chimneys all over the world, which are dangerous for health and life of citizens.

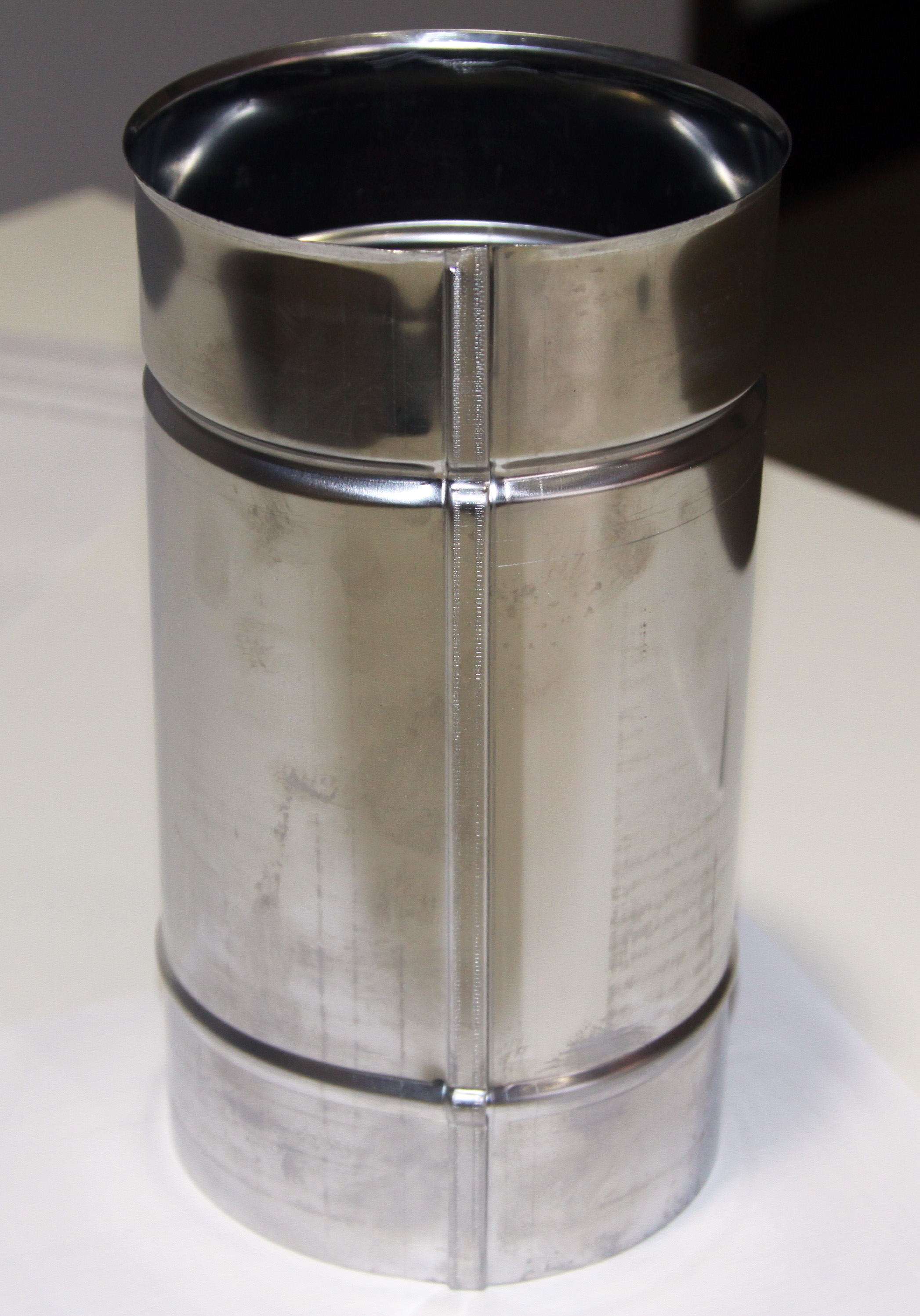

Stainless steel chimneys

The main requirements for modern chimney are resistance to high temperatures and condensation. If the first requirement is met by almost all non-combustible materials, the second one eliminates porous materials (asbestos-cement, brick), and became a subject to corrosion. Thanks to the acid resistance of stainless steel has become the most common material in the production of flue-gas technology.

Modular stainless steel chimney has a number of advantages:

- flue system of any configuration can be assembled of the individual elements, which is very important when the house is already built

- easy and quick to install

- do not require a base

- universal ( suits to any king of fuel)

- resistant to high temperatures

- resistant to corrosion

To choose highly qualified chimney you should pay attention at some aspects:

- The longitudinal seam of the pipes must be welded in an automatic manner. The welding method is WIG / TIG in an inert gas environment (argon), because only in this case the seam will be protected from the effects of flue gases and condensate.

- The socket connections of all segments of the chimney must have a groove under the seal, to ensure the gas density of the chimney system.

- A heat insulation material used in chimney systems must have a certificate of conformity and be clearly fixed inside the pipe. The fixing of the heater must be done by means of devices that transfer the heat from the inner tube to the outside.

Only if the above technological nuances are observed, the chimney system is suitable for operation and will provide the nominal efficiency of the heating device.

Pipe samples of tin workshops

Despite the high popularity of stainless steel chimneys and their widespread use in construction, the legislation still allows using practically any non-combustible materials in the chimney technique, and the absence of a national standard contributes to the appearance of dubious pipes of dubious origin on the market...

Disadvantages:

Traces of rust on the inside surface of the pipe talk about using cheap grades of stainless steel, which is taken by a magnet, a testament to its ferritic structure.

- The longitudinal seam of the tube is not welded thoroughly, but used only spot welding

- The mounting clamps are not provided, because the chimney is not falling apart, it is necessary to fix the pipe together with rivets or screws, breaking the seal

- On the right photo, we are dealing with almost the same quality of tubes made in the workshops, but instead of welding seam is just rolled up in a "lock". Disadvantage of the weld is that at high temperatures and cyclic heating-cooling it can disperse by thermal expansions.

In addition to tin workshop also operates a number of businesses engaged in production of stainless steel chimneys.

The quality of these products is certainly better than the quality in tin shops, because the factory is able to use special equipment for cutting, rolling, welding and other industrial processes. However, these chimneys do not correspond all the requirements for modern chimney.

The longitudinal seam of pipe, which is made of segments welded butt automatic welding, but seams connecting segments knee are manually welded, which can lead to inaccuracy in the geometry of the product.

After manual welding, the seam is not cleaned, although it looks more aesthetically on the sample on the left, because it is painted with silver.

The thickness of insulation in insulated pipes of every manufacturer is the same - the average is 30-35 mm. On the left the manufacturer fixes the heater with a continuous ring of galvanized steel, which contributes to heat transfer from the inner tube (the temperature of which in some cases can be up to 600 ˚ C) to the outer shell, which is not very good for the fire safety of the chimney. The second sample does not have lock rings, the inner tube is removed freely. On the one hand the lack of rings means no contact with the outside of the inner tube, but on the other - who knows how much heater was in a pipe, and how much was dropped out of stock during delivery to the object and installation ... In addition, the casing of the pipe is made of Ferritic stainless steel (label 430 is the steel grade).

It should be noted that on all types of pipes of domestic manufacturers there is not enough groove under the seal, although the tightness is one of the main requirements of the chimney.

The benefits of high-quality chimney systems

Modern chimney should be:

- Resistant to high temperatures

- Corrosion resistant

- Sealed

To comply with these requirements, all parts of the flue system must be produced exclusively in the factory and on equipment designed for manufacturing elements of chimney systems. Due to the lack of special equipment some manufacturers have to compromise on the issue of product quality.

Even if these compromises lead to lower product prices, the purchase of a chimney system is hardly savings. Often, chimneys of poor quality lead to serious consequences, which can be avoided if you pay attention to the following points:

- Pay attention to the longitudinal seam pipe - it should be welded by automatic means.

- Welding method - WIG / TIG inert gas (argon), since only in this case the seam is protected against the flue gases and condensate.

- Push-fit connection of all segments of the chimney should have a groove under seal, to ensure the gas tightness of the flue-gas system.

- Insulation used in the flue system must have a certificate of conformity and be clearly fixed inside the pipe.

- Fixing insulation should occur with devices transmit heat from the lowest inside to the outside of the pipe.

Only in accordance with the above-mentioned technological nuances flue system is suitable for the operation and provide the nominal efficiency of the heating appliance.